Tinjauan

304 stainless steel mangrupakeun jenis bahan stainless steel universal, résistansi karat téh kuat ti 200 runtuyan bahan stainless steel, résistansi suhu luhur oge hadé, bisa nepi ka 1000-1200 degrees.304 stainless steel boga résistansi korosi alus teuing jeung résistansi korosi antara grains.For asam pangoksidasi, dina percobaan: konsentrasi ≤65% asam korosi, suhu ngagolakkeun ≤65% stainless steel. gaduh résistansi korosi anu hadé pikeun solusi basa sareng kalolobaan asam organik sareng anorganik.

Spésifikasi

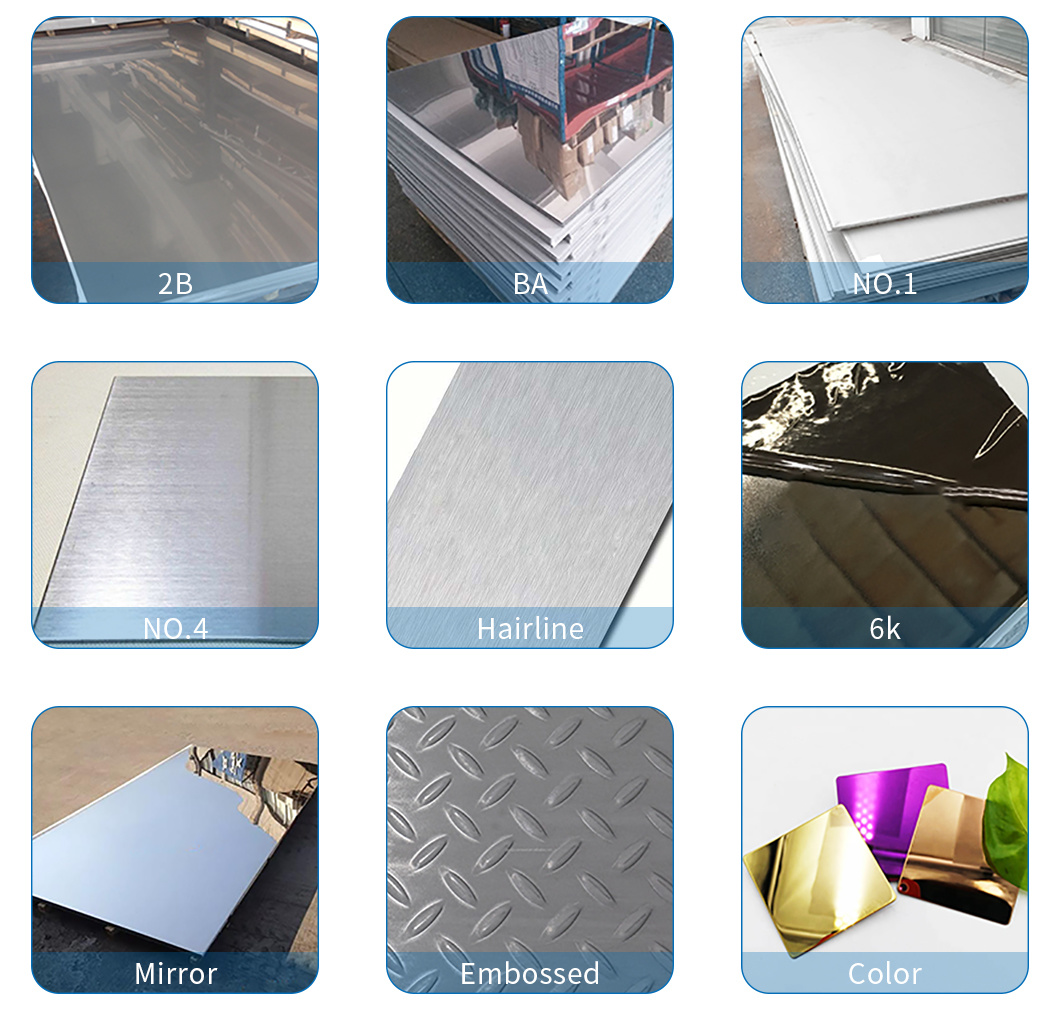

| Surface Finish | Katerangan |

| 2B | A finish caang, sanggeus rolling tiis, ku perlakuan panas, bisa dipaké langsung, atawa salaku hambalan awal ngagosok. |

| 2D | Permukaan anu kusam, anu balukar tina ngagulung tiis dituturkeun ku annealing sareng descaling. Ieu bisa meunang roll lampu final ngaliwatan gulungan unpolished. |

| BA | Caang Annealed finish nu diala ku annealing bahan dina hiji atmosfir sahingga skala teu ngahasilkeun dina beungeut cai. |

| No.1 | A kasar, finish kusam, nu hasil tina rolling panas kana ketebalan dieusian. Dituturkeun ku annealing sareng descaling. |

| No.3 | finish ieu digosok ku No.100 mun No.120 abrasive dieusian dina JIS R6001. |

| No.4 | finish ieu digosok ku No.150 mun No.180 abrasive dieusian dina JIS R6001. |

| Garis rambut | A finish geulis, ditangtayungan ku pilem PVC saméméh ngagunakeun, dipaké dina kitchenware, |

| 8K Eunteung | The "8" dina 8K nujul kana proporsi komponén alloy (304 stainless steel utamana nujul kana eusi elemen), "K" nujul kana kelas reflectivity sanggeus polishing. Beungeut eunteung 8K nyaéta kelas permukaan eunteung anu dicerminkeun ku baja alloy nikel krom. |

| Emboss | Lambaran stainless steel embossed mangrupakeun bahan serbaguna dipaké pikeun nyieun éfék hiasan dina beungeut logam. Éta mangrupikeun pilihan anu saé pikeun proyék arsitéktur, splashbacks, signage, sareng seueur deui. Éta pisan énténg, sareng aranjeunna tiasa dibentuk pikeun nyumponan spésifikasi tina sababaraha aplikasi anu béda. |

| Warna | Warna Steel nyaeta titanium coated stainless steel. Warna dimeunangkeun ku ngagunakeun prosés turunan PVD. Bentuk dina beungeut unggal lambar nyadiakeun tipena béda palapis, kayaning oksida, nitrides jeung karbida. |

Mangpaat Utama nyaéta

1. Used pikeun ngolah sagala jinis patempatan konvensional sarta pikeun stamping paeh;

2.Used salaku bagian mékanis precision tinggi tina baja;

3. Hal ieu loba dipaké dina prosés perlakuan panas annealing relief stress saméméh bending.

4. Ieu bisa dipaké salaku bahan wangunan pikeun konstruksi sipil.

7. Ieu bisa dipaké dina industri mobil.

8. Ieu bisa dilarapkeun ka industri Perkakas rumah tangga. Sektor énergi nuklir. Spasi jeung aviation. Médan éléktronik sareng listrik. Industri mesin médis. Industri galangan kapal.

Komposisi kimia tina stainless steel biasa dipaké

| Kelas | C | Si | Mn | P | S | Ni | Cr | Mo | Lain |

| 304 | ≤0.07 | ≤0.75 | ≤2.00 | ≤0,045 | ≤0,030 | 8.0/10.5 | 17.5/19.5 | ― | N≤0.10 |

| 304H | 0.04/0.10 | ≤0.75 | ≤2.00 | ≤0,045 | ≤0,030 | 8.0/10.5 | 18.0/20.0 | ― | |

| 304L | ≤0,030 | ≤0.75 | ≤2.00 | ≤0,045 | ≤0,030 | 8.0/12.0 | 17.5/19.5 | ― | N≤0.10 |

| 304N | ≤0.08 | ≤0.75 | ≤2.00 | ≤0,045 | ≤0,030 | 8.0/10.5 | 18.0/20.0 | ― | N: 0.10/0.16 |

| 304LN | ≤0,030 | ≤0.75 | ≤2.00 | ≤0,045 | ≤0,030 | 8.0/12.0 | 18.0/20.0 | ― | N: 0.10/0.16 |

| 309S | ≤0.08 | ≤0.75 | ≤2.00 | ≤0,045 | ≤0,030 | 12.0/15.0 | 22.0/24.0 | ― | |

| 310S | ≤0.08 | ≤1,50 | ≤2.00 | ≤0,045 | ≤0,030 | 19.0/22.0 | 24.0/26.0 | ― | |

| 316 | ≤0.08 | ≤0.75 | ≤2.00 | ≤0,045 | ≤0,030 | 10.0/14.0 | 16.0/18.0 | 2.00 / 3.00 | N≤0.10 |

| 316L | ≤0,030 | ≤0.75 | ≤2.00 | ≤0,045 | ≤0,030 | 10.0/14.0 | 16.0/18.0 | 2.00 / 3.00 | N≤0.10 |

| 316H | 0.04/0.10 | ≤0.75 | ≤2.00 | ≤0,045 | ≤0,030 | 10.0/14.0 | 16.0/18.0 | 2.00 / 3.00 | |

| 316LN | ≤0,030 | ≤0.75 | ≤2.00 | ≤0,045 | ≤0,030 | 10.0/14.0 | 16.0/18.0 | 2.00 / 3.00 | N: 0.10/0.16 |

| 317L | ≤0,030 | ≤0.75 | ≤2.00 | ≤0,045 | ≤0,030 | 11.0/15.0 | 18.0/20.0 | 3.0/4.0 | N≤0.10 |

| 317LN | ≤0,030 | ≤0.75 | ≤2.00 | ≤0,045 | ≤0,030 | 11.0/15.0 | 18.0/20.0 | 3.0/4.0 | N: 0.10/0.22 |

| 321 | ≤0.08 | ≤0.75 | ≤2.00 | ≤0,045 | ≤0,030 | 9.0/12.0 | 17.0/19.0 | ― | N≤0,10Ti:5ʷʢC+Nʣ/0,70 |

| 347 | ≤0.08 | ≤0.75 | ≤2.00 | ≤0,045 | ≤0,030 | 9.0/13.0 | 17.0/19.0 | ― | Nb: 10ʷC/1.00 |

| 904L | ≤0,020 | ≤1.00 | ≤2.00 | ≤0,045 | ≤0,035 | 23.0/28.0 | 19.0/23.0 | 4.00 / 5.00 | N≤0.10Cu:1.0/2.0 |

-

201 304 Eunteung Warna Stainless Steel Lambaran di S ...

-

316L 2B Checkered Stainless Steel Lambaran

-

304 Warna Stainless Steel Lambaran Etching Pelat

-

430 Lambaran Stainless Steel Perforated

-

SUS304 Embossed Lambaran Stainless Steel

-

201 J1 J3 J5 lambaran stainless steel

-

Lambaran Stainless Steel Perforated

-

PVD 316 Lambaran stainless steel berwarna

-

SUS304 BA lambaran stainless steel Laju pangalusna

-

SUS316 BA 2B lambaran stainless steel suppliers